Laser type (standard type/high pressure type)

Optical Floating Zone Furnaces

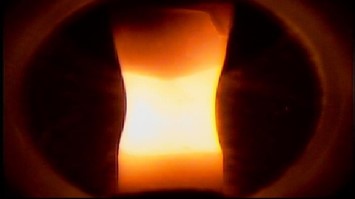

Our laser FZ furnaces use localized heating to minimize thermal effects outside the melted area, enabling the crystallization of a wide variety of materials. Real-time monitoring using Infrared thermometer (Pyrometer) and video ensures stable and reproducible growth.

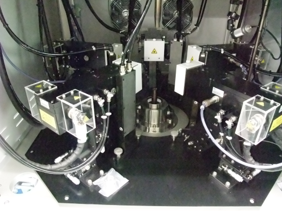

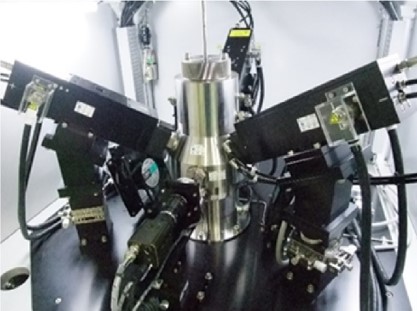

Product Photos

Product Introduction

Our laser single crystal growth furnaces use the laser floating zone (FZ) method, which minimizes the thermal impact on areas other than the molten area through localized heating using a sharp temperature gradient. It is also highly effective in crystallizing decomposed molten materials, which was difficult with conventional lamp heating methods. Furthermore, by incorporating a Infrared thermometer (Pyrometer) and real-time monitoring function using video, we have achieved a highly reproducible crystal growth process.

Uniform heating with multiple laser diodes

Multiple laser diodes, evenly spaced apart, heat the melting zone uniformly, minimizing temperature variations and improving interface smoothness and reproducibility.

Steep temperature gradients allow for decomposition-melting materials

The temperature gradient is steeper than lamp heating, enabling the growth of decomposition-melting materials such as BiFeO₃ and (La,Ba)₂CuO₄, which were previously difficult to grow using conventional methods.

Wide Growth Speed Range

Slow feed: 0.01 to 300 mm/h, fast feed: 1 to 150 mm/min. Flexible control from ultra-low to high speeds is possible, making it compatible with a variety of material.

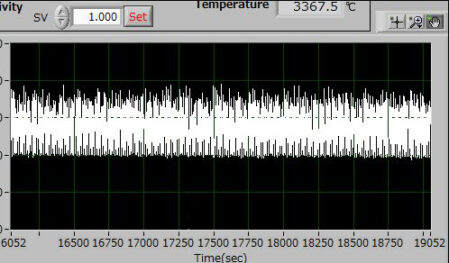

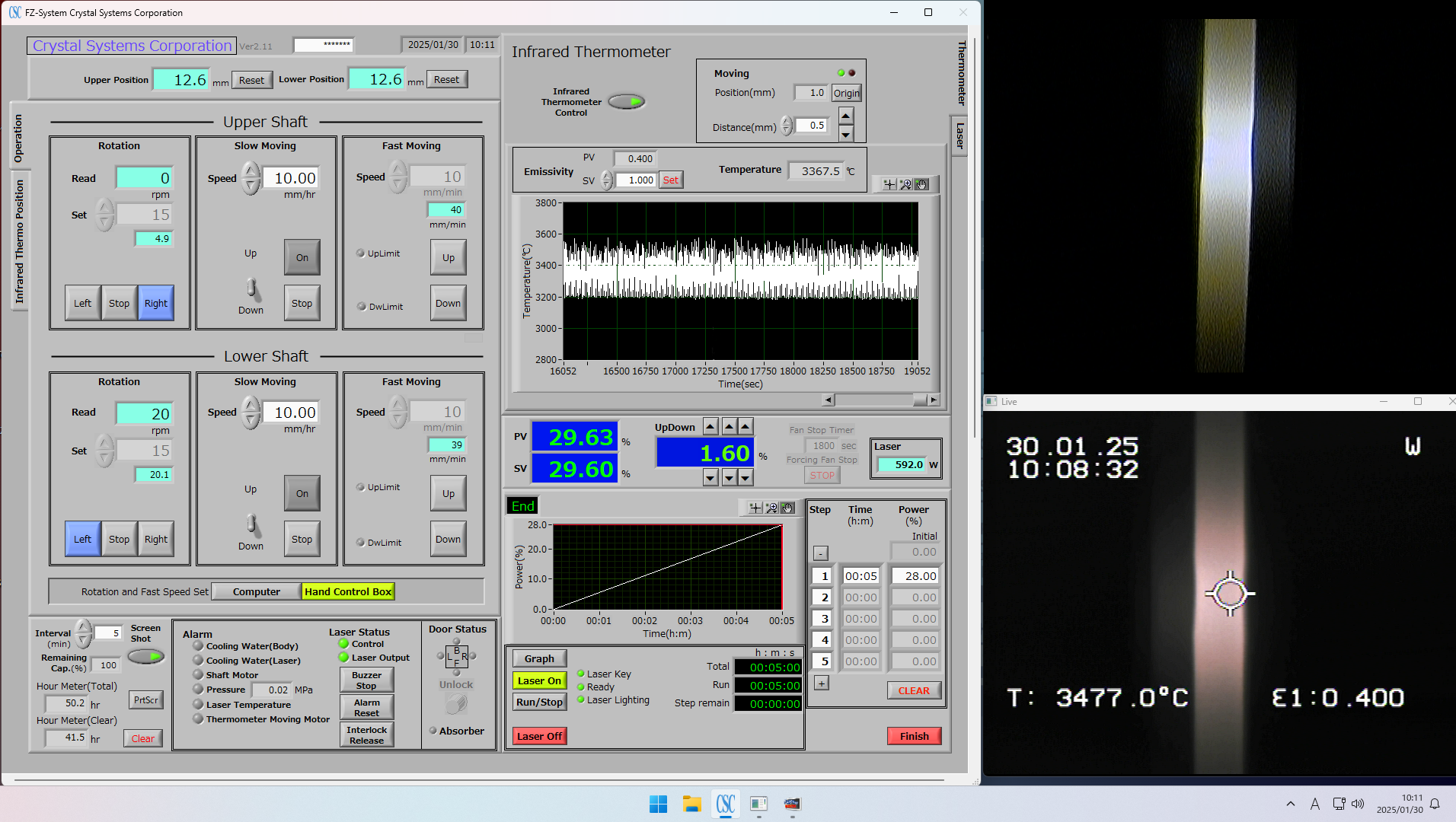

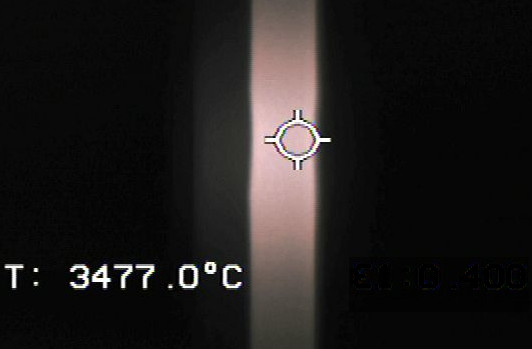

Real-Time Process Monitoring

Continuously monitor temperatures and conditions with live monitoring using Infrared thermometer (Pyrometer) and video. The PC-based GUI provides high operability and flexible software updates and customization.

Temperature Gradient Measurement Using a Infrared thermometer (Pyrometer) (Standard Type)

Automatically measures the vertical temperature gradient to precisely monitor the condition of the crystal during growth.

Selectable High-Power Laser Modules (Standard Type)

Equipped with five 200 W modules as standard (1 kW total), with an option to upgrade to five 500 W modules (up to 2.5 kW total). Capable of processing ultra-high-temperature materials such as tungsten (melting point over 3400 °C).

Variable/Fixed Beam Angle Mechanism

The standard type features an adjustable beam angle between 0° and 30°. The high-pressure model has a fixed angle of 30°, making it compatible with high-pressure techniques such as the SCFZ method.

Crystal Growth Under Vacuum and High-Pressure Atmospheres

The standard model, when equipped with an optional vacuum pump, achieves high vacuum levels of 6.7 × 10⁻³ Pa or better, and supports crystal growth under high-pressure atmospheres up to 0.95 MPa. The high-pressure model allows crystal growth under pressures up to 15 MPa.

Customizable Equipment

Customization is possible based on customer needs.

Examples:

Automated tilt laser beam unit system

Laser beam size conversion units

- Gas guide(Halogen type, Xenon type, LazerFZ)

- After heater unit(LazerFZ, Halogen type only)

Full Support System

We respond to any issues within 1-2 days (sometimes remotely).

We provide honest and courteous support, even for equipment you’ve used for over 20 years.

We also support equipment from other manufacturers.

Product Lineup

FZ-LD-3-500W-II-VPO-PC-HP

High-pressure type